HDPE is a common type of plastic with its own characteristics and properties that are easy to distinguish. In particular, they can also be easily recycled, helping to protect the living environment. In the following article, TAELIM will provide information about this type of plastic and its characteristics for you to understand.

Overview of HDPE plastic

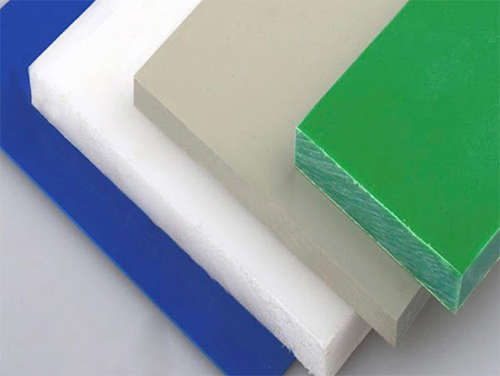

HDPE, short for “High Density Polyethylene”, is a type of plastic produced from petroleum. Thanks to its high-density molecular structure, HDPE often has high thickness, hardness, and impact resistance, and tensile strength superior to conventional PE plastics. This is a synthetic plastic that is commonly used in both industrial production and daily life.

HDPE plastic is produced through the polymerization of ethylene under low pressure conditions, along with catalysts such as chromium or silicon catalysts. The molecular structure of HDPE includes long chains of ethylene linked together, which helps create flexibility and the ability to withstand high pressure and impact. In addition, HDPE is also resistant to dissolution and corrosion caused by chemicals and environmental factors. Because of these outstanding properties, HDPE plastic is widely used to produce plastic bags, plastic sheets, and many other plastic tools.

>>> See more: Applications of HDPE and Basic Standards When Using

Properties of HDPE plastic

HDPE, or High Density Polyethylene, has a simple molecular structure with ethylene units linked together, creating a strong and durable molecular network. Below are some outstanding properties of High Density Polyethylene for you to understand.

Chemical resistance

HDPE is highly sought after for its resistance to a wide range of chemicals. It is resistant to acids, alkalis, and many organic compounds, making it an ideal choice for chemical-related applications, such as tanks and fluid transfer systems.

Water and moisture resistant

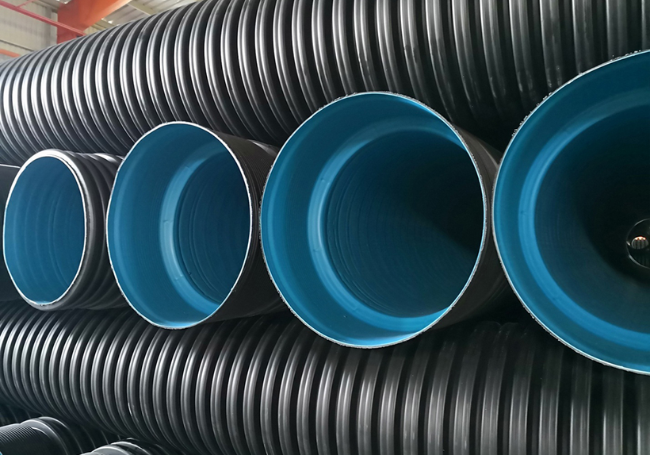

High Density Polyethylene does not absorb water and has excellent water resistance. This makes them the top choice for water-related applications such as plumbing and water treatment systems. The water resistance also ensures that this plastic is waterproof and does not deform in wet conditions.

Good thermal and mechanical properties of HDPE

High Density Polyethylene has excellent thermal and mechanical properties, making it resistant to the effects of temperature and pressure. With high mechanical strength, this plastic can withstand force and impact without deformation, making it suitable for applications that require durability and stability, such as the production of tanks or outdoor furniture.

Good elasticity

High Density Polyethylene has the ability to stretch and return to its original shape after being deformed. This makes it an ideal choice for applications that require elasticity, such as the production of plastic bags, plastic bottles and many other flexible products.

Answering the question: Is HDPE plastic toxic?

High Density Polyethylene is considered safe for human health and the environment, as it does not contain toxic compounds such as lead, mercury or phthalates. However, you need to note some important points during use:

When exposed to temperatures exceeding 120 degrees Celsius, HDPE plastic can decompose and produce toxic gases, which are hazardous to health. Therefore, High Density Polyethylene should not be used in high temperature environments or near strong heat sources.

High Density Polyethylene is not resistant to UV rays from sunlight. UV rays can cause fading and loss of strength, leading to deformation and loss of elasticity in products made from this type of plastic.

In case of swallowing HDPE plastic items, such as marbles, it can cause gastrointestinal obstruction or other digestive problems. Therefore, it is necessary to prevent children from coming into contact with and swallowing small plastic products. Thus, High Density Polyethylene is considered safe, but caution is still needed.

>>> See more: Characteristics and Applications of PVC Plastic Granules in Life

Is HDPE plastic reusable?

The answer is yes. High Density Polyethylene is one of the easiest plastics to recycle. To identify this plastic, you can look for the identification code printed on the bottom of the can or lid of the product, with the number 2 inside a recycling arrow. The recycling process for HDPE plastic includes the following steps:

Step 1: Collect High Density Polyethylene

During the collection process, the separation of clean and dirty plastics takes place simultaneously, because the two types have different recycling values. Plastics are very susceptible to contamination, so separation and storage are extremely important. Dirty plastics need to be treated and cleaned before recycling to ensure quality.

Step 2: HDPE Recycling

High Density Polyethylene is shredded and melted to create small plastic pellets. These plastic pellets can then be used to manufacture new products or for injection molding applications. Injection molding is the most common recycling method, used in mass and continuous production.

>>> See more: 1001 Great Benefits of Purchasing and Recycling Waste Paper

Recently, TAELIM introduced HDPE plastic and its characteristics as well as answered related questions. Hopefully, through this, you have a better understanding of this type of plastic and can easily use it in your daily life.

TAELIM International Transport Company Limited

With the desire to support the development of the plastic industry by providing high quality plastic pellets and services. Taelim Plastic is one of the Vietnamese plastic companies with many years of experience, with a long history of development, specializing in the production, trading, import and export of recycled pellets. By applying advanced technology, meeting European standards with a strict process, we ensure to bring customers the best products and services.

ADDRESS: SH109 Vinhomes Marina, Hai Phong

PHONE: (+84) 9815 888 16

EMAIL: hatnhua.taelim@gmail.com