Plastic pellets are an indispensable ingredient to create common products in our daily lives. Currently, there are many different types of plastic on the market suitable for manufacturing. In the following article, Taelim Plastic will share basic information about this material and classify it in detail for you to understand.

Find out what plastic beads are?

Plastic masterbatches, also known as masterbatches, are small particles used as the main raw material in the production of plastic products. To create a complete plastic product, the base masterbatch will be mixed with other ingredients such as color masterbatches, CaCo3 fillers, and other plastic additives to achieve the desired final product.

Classification of plastic beads on the market

Currently, this type of plastic is divided into many different groups and is usually divided by origin. Therefore, there are 3 main types: fossil plastic, recycled plastic and bioplastic. Below

Virgin plastic (fossil plastic)

Virgin plastic is a type of plastic produced directly from petroleum, without any impurities or additives, so they are usually naturally white. To create virgin plastic products with other colors, it is necessary to add pigments or other color particles according to a specific formula to achieve the desired color.

Currently, there are several popular types of virgin plastic on the market including ABS, PP, PC, PS-GPPS, PA, HIPS, POM, PMMA, etc. Each of these types of plastic will be used according to different formulas and proportions to suit the specific requirements of the final product. Virgin plastic stands out for its flexibility, high elasticity, and good resistance to warping. Products made from virgin plastic often have a glossy, smooth surface, with bright colors.

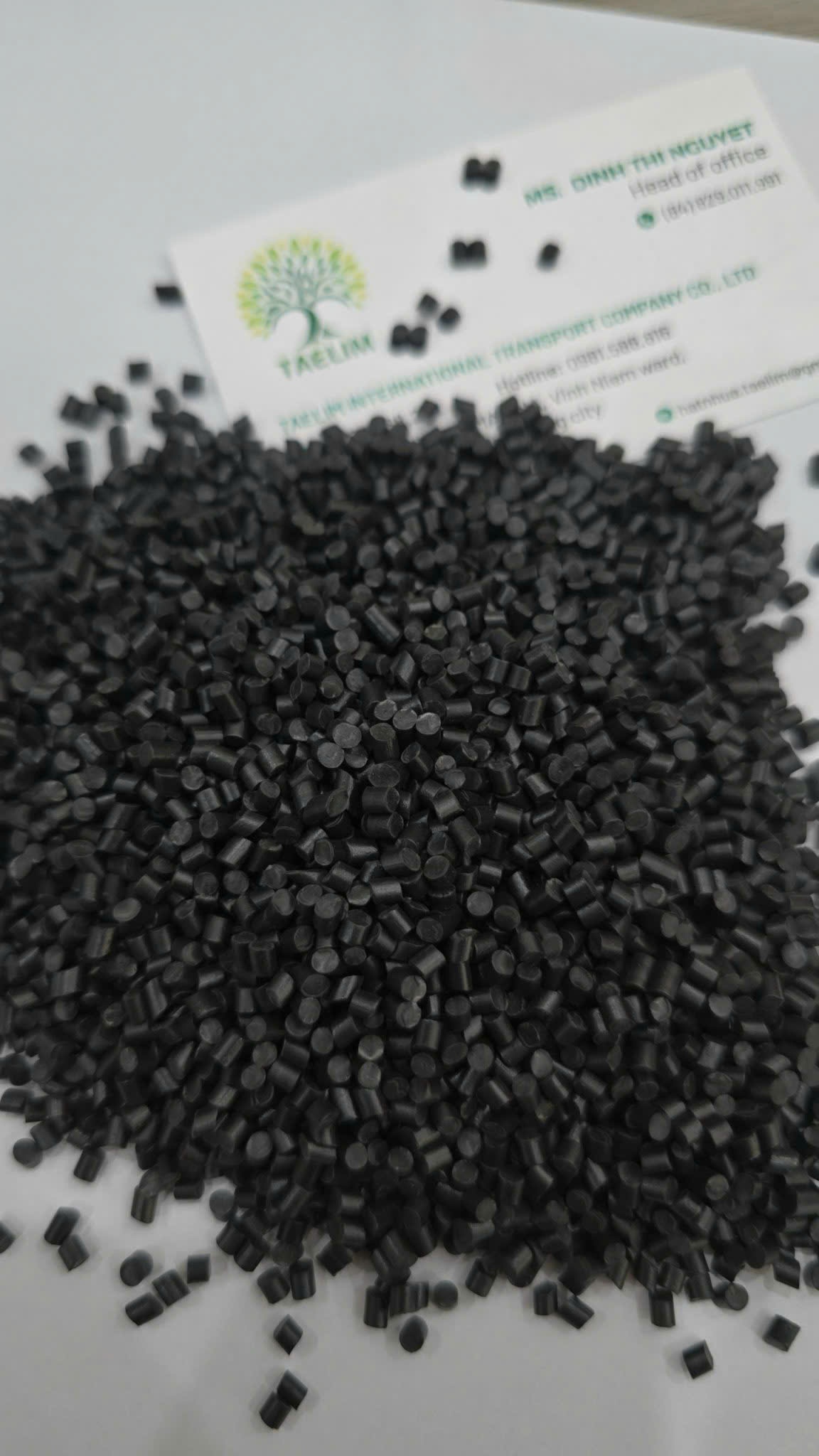

Recycled plastic pellets

Recycled plastic is a type of granule that is regenerated from old or waste plastic products, such as bottles, household appliances, and used machinery. The process of producing recycled plastic includes steps such as sorting, crushing, cleaning, drying, and melting, thereby creating plastic fibers or plastic granules.

Recycled plastic is essentially a recycled product from virgin plastic, so any type of virgin plastic on the market will have corresponding types of recycled plastic. Due to the recycling process, recycled plastic often has reduced properties compared to virgin plastic, but is still widely used due to its economic and environmental friendliness.

Bioplastic granules

Different from the two types of plastic above, bioplastic is produced from natural materials such as starch, protein, cellulose. This type of plastic is outstanding for its ability to self-decompose and does not pollute the environment. Currently, they are commonly used in the production of food contact utensils such as trays, spoons, forks, straws, packaging, plastic bags, and water bottles.

Synthesis of plastic granules production

Besides classifying by origin, you can base on chemical composition characteristics. Below are the types of plastic classified by this factor for you to understand clearly.

PP plastic granules

PP (Polypropylene) plastic is a type of plastic with high mechanical strength. Products made from PP plastic are often transparent, colorless, odorless, and non-toxic, with the ability to withstand heat up to 100 degrees Celsius and a melting temperature of 165 degrees Celsius.

PP plastic is widely used in the production of packaging, cement bags, animal feed bags, household products such as ladles, cups, food containers, as well as in plastic components, waterproof membranes, plastic boards, and plastic floors.

PE plastic granules

PE (Polyethylene) is a flexible granule with a variable crystal structure. The outstanding properties of PE plastic are its ability to insulate, insulate and waterproof effectively. In terms of color, PE is usually clear white, and depending on the needs of use, manufacturers can add granules or pigments to create the desired color.

PE plastic is considered the safest of all virgin plastics. However, despite its high flexibility, PE plastic is not exceptionally durable and is easily scratched on the surface. PE plastic has a wide range of applications, including plastic packaging, wire sheathing, plastic film, label coating, and products such as crates, trays, bottles, and plastic bottle caps.

ABS plastic beads

ABS (Acrylonitrile Butadiene Styrene) plastic is a hard but not brittle plastic with good impact resistance. Similar to PE and PP plastics, ABS plastic is electrically insulating, waterproof and resistant to high temperatures and chemicals. Moreover, ABS plastic is easy to process and shape, so it is widely used in many manufacturing industries.

With these superior properties, ABS plastic is often used to produce electrical outlet covers, electrical panels, blender covers, juicers, ovens, egg beaters, electric hot pots, car and motorbike engine parts, containers, special packaging, helmets, etc.

HDPE plastic granules

HDPE (High Density Polyethylene) is produced by heating high density ethylene under low pressure conditions and using catalysts such as chromium or silicon. HDPE plastic is very durable and can withstand all environmental pressures. Specifically, this type of plastic is resistant to corrosion by water, wind, rain, concentrated acids, alkalis, salts and even ultraviolet rays.

Thanks to these characteristics, HDPE plastic has a long life and is less susceptible to aging over time. Therefore, it is often used to produce drainage pipes, plastic pipes, large-sized waste pipes, electrical conduits, hot and cold water pipes, hot air pipes, and electric cables.

LDPE plastic granules

LDPE (Low Density Polyethylene) is a variant of PE with a lower density of Polyethylene. They inherit the advantages of PE such as resistance to acids, alkalis and organic solvents, along with good electrical insulation.

In addition, LDPE is lightweight, impact resistant, moisture resistant, effective insulator and insulator, and is not affected by external environmental factors. Therefore, they are widely used in life, from the production of plastic barrels, food containers, knife/scissor handles, fish tanks, to windproof roofs, etc.

PVC plastic granules

PVC (Polyvinyl Chloride) is the first plastic created from the artificial synthesis of vinyl chloride when exposed to sunlight. They are resistant to rain, wind, corrosion, shock and abrasion. It is less likely to spread fire to other materials because PVC's ignition temperature is up to 455°C. Under normal conditions, PVC is hard, brittle, strong, light and flexible. PVC can dissolve or swell in aromatic hydrocarbons, ketones and ethers.

PVC plastic is widely used in daily life with applications such as underground water pipes, communication cables, insulating tapes, civil electric cables, switch boxes and wire covers, medical instruments, etc.

HIPS resin

HIPS (High Impact Polystyrene) is a variant of PS plastic with high impact resistance. This type of plastic has a flash point of 175°C and a structure that prevents bacteria from growing, making it harmless to human health.

HIPS is hard, transparent, easy to color and is often processed by vacuum forming or simple pressing. Thanks to that, they will be widely used in the production of products such as motorcycle tires, televisions, trays, boxes, disposable dishes, etc.

GPPS plastic granules

GPPS (General Purpose Polystyrene) is a hard, transparent, colorless, odorless and easy-to-color plastic. With low molecular weight, GPPS has poor durability at high temperatures and is brittle. In particular, they will start to melt and become sticky at temperatures above 80°C. This type of plastic is often used to produce foam boxes, food trays, CDs, children's toys, stationery, etc.

PET plastic beads

PET (Polyethylene Terephthalate) is a thermoplastic, formed from the polymerization reaction between ethylene terephthalate monomers. PET plastic has good resistance to force and temperature, maintaining a stable chemical structure at temperatures from -90 to 200°C.

PET has high mechanical strength, good tear and impact resistance, glossy and smooth surface, but has many small, porous holes, difficult to clean. In life, PET plastic is often used to produce water bottles, food trays, handmade fibers in garments, plastic straws, etc.

Conclusion

Above, TAELIM has provided detailed information about plastic beads and detailed classification. This is a common ingredient in the industry of manufacturing household appliances, materials, etc. today. Hopefully, through this, you have a better understanding of this material and can easily choose the right type of beads.

>>> See more: Applications of Plastic Beads in Production and Life

TAELIM International Transport Company Limited

With the desire to support the development of the plastic industry by providing high quality plastic pellets and services. Taelim Plastic is one of the Vietnamese plastic companies with many years of experience, with a long history of development, specializing in the production, trading, import and export of recycled pellets. By applying advanced technology, meeting European standards with a strict process, we ensure to bring customers the best products and services.

ADDRESS: SH109 Vinhomes Marina, Hai Phong

PHONE: (+84) 9815 888 16

EMAIL: hatnhua.taelim@gmail.com