HDPE plastic is a popular material with distinct properties. In the following article, TAELIM will introduce basic information about this type of plastic and answer related questions for customers.

Introduction to basic information about HDPE plastic

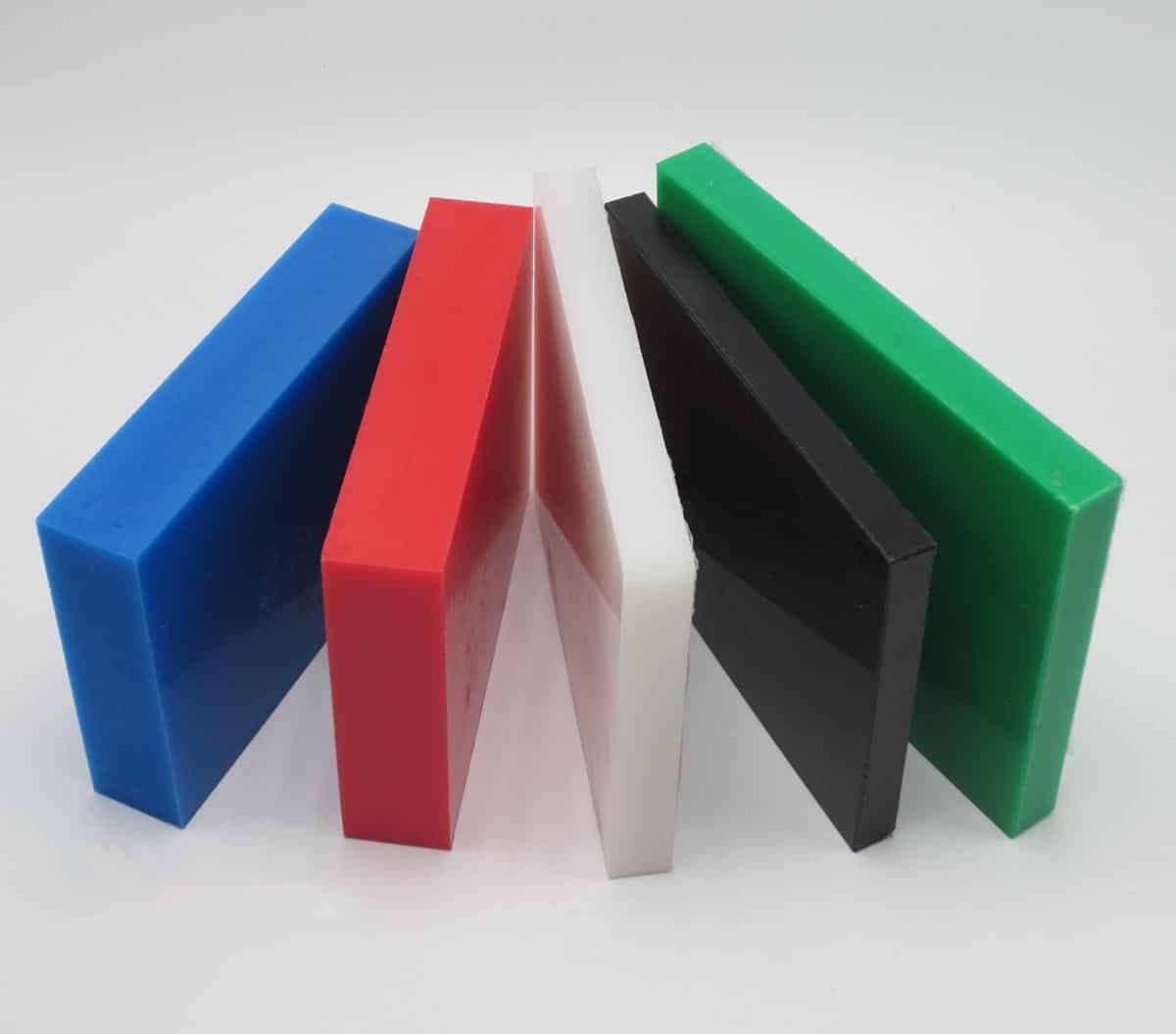

High-Density Polyethylene (HDPE) is a form of polyethylene that is high-density, has few branches, and has strong intermolecular forces, providing superior tensile strength. It is one of the most widely used plastics in the world, with the chemical formula (C2H4)n, made up of repeating ethylene monomer units.

The HDPE plastic production process takes place under low pressure, using catalysts such as chromium or silyoc catalyst, creating a special molecular structure. Thanks to that, HDPE has the ability to withstand force, impact, and chemicals, and is not dissolved or corroded. With its flexibility and high durability, HDPE is often used to produce plastic bags and many other plastic products in life and industry.

>>> See more: Distinguishing PE Plastic and Important Notes When Using

Properties of HDPE plastic

HDPE stands out with many superior properties, making it the top choice in many fields. First, this plastic has very high durability, resists corrosion from the natural environment as well as strong chemicals.

In addition, HDPE is also able to withstand the effects of sunlight and ultraviolet rays without cracking or deteriorating over time. With a long life, no aging or rusting, HDPE is suitable for use in harsh conditions.

HDPE plastic can withstand low to high temperatures, has good elasticity and flexibility, making it easy to bend when used in construction. In particular, this plastic is lightweight, ideal for making household items or pipes in cold environments. HDPE is also known for its fire resistance and high pressure resistance, suitable for use in chemical plants.

Thanks to its outstanding properties, HDPE plastic is popular in the production of everything from household appliances to sturdy pipes. This is truly a great material, meeting many strict requirements in different applications.

Advantages and disadvantages of HDPE plastic

HDPE offers many outstanding advantages, making it a popular material in many industries. First, HDPE is very safe to use, environmentally friendly, and easy to recycle. In particular, it has the ability to be flexible and shaped into many products with different shapes and sizes. With its light weight, HDPE plastic is easy to transport and has high durability, effectively resisting impact and scratches. In particular, it is also anti-static, resistant to chemicals and non-corrosive.

However, HDPE also has some limitations. One of its disadvantages is its poor resistance to ultraviolet (UV) rays, which leads to deterioration when exposed to sunlight for a long time. When exposed to high temperatures, HDPE is prone to expansion, and its stiffness is lower than that of Polypropylene (PP). In addition, the welds between these plastic pieces can also be easily damaged by sudden temperature changes, leading to cracking.

Frequently Asked Questions about HDPE Plastic

With the basic information above, you must have understood this type of plastic. However, there are still some related questions that will be answered specifically below.

Is HDPE plastic safe to use?

HDPE is considered safe and does not contain toxic additives such as Bisphenol A (BPA) or Phthalate. When exposed to the environment, it does not release pollutants. Therefore, products made from this type of plastic are considered safe for human health.

What is HDPE pipe?

HDPE pipes are made from high-density thermoplastic, also known as Polyethylene High-Density (PEHD). With outstanding durability and resistance to chemical corrosion, HDPE pipes often have a lifespan of up to 50 years, do not leak at the welds, helping to ensure durability and safety in industrial applications.

What is the melting point of HDPE plastic?

The melting point of HDPE is typically between 120°C and 180°C (248°F and 356°F). Depending on the specific HDPE grade and additives, this temperature can vary slightly.

Recently, TAELIM has provided information about HDPE plastic, with its outstanding properties and flexible applications, it is still the top choice for many fields. Hopefully, through this, you have a better understanding of this popular plastic.

>>> See more: Applications of HDPE and Basic Standards When Using

TAELIM International Transport Company Limited

With the desire to support the development of the plastic industry by providing high quality plastic pellets and services. Taelim Plastic is one of the Vietnamese plastic companies with many years of experience, with a long history of development, specializing in the production, trading, import and export of recycled pellets. By applying advanced technology, meeting European standards with a strict process, we ensure to bring customers the best products and services.

ADDRESS: SH109 Vinhomes Marina, Hai Phong

PHONE: (+84) 9815 888 16

EMAIL: hatnhua.taelim@gmail.com