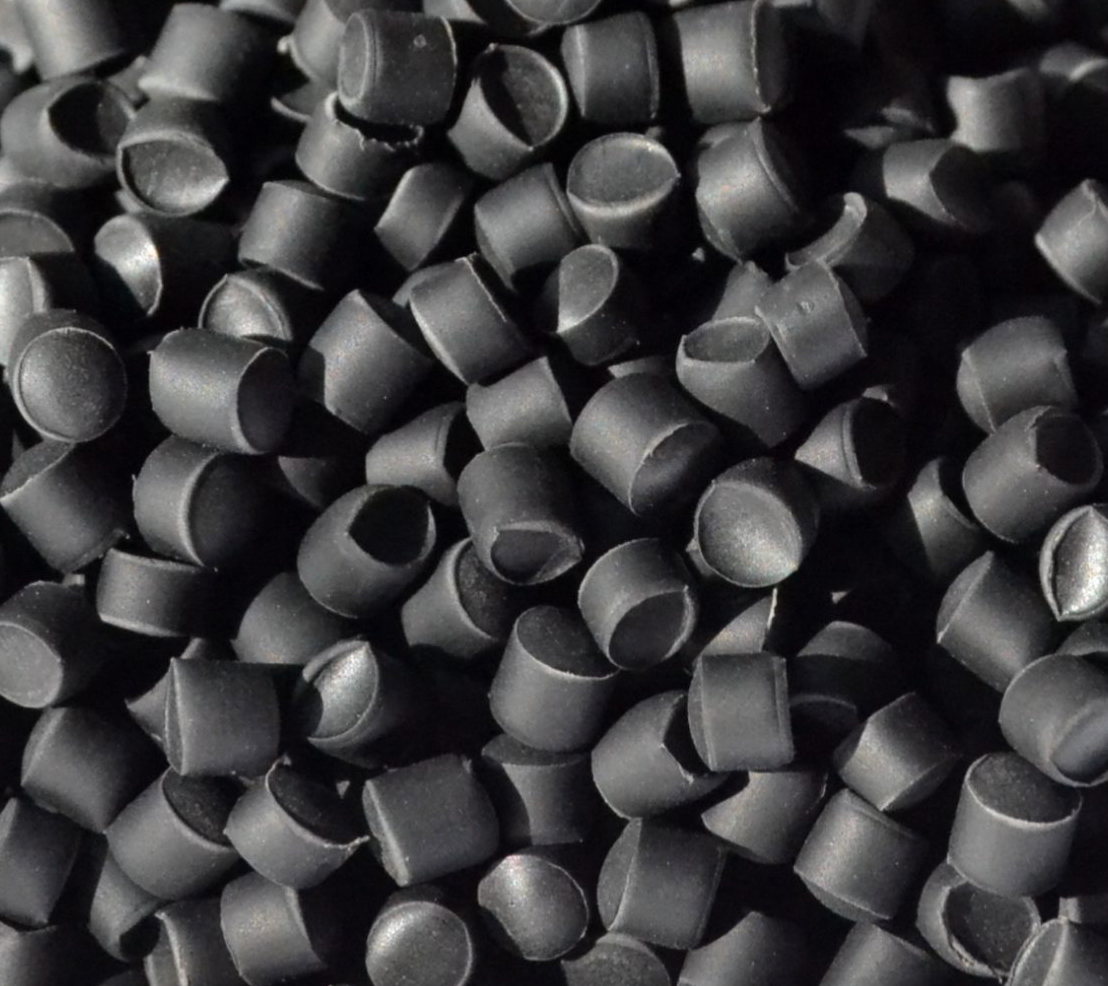

PVC plastic granules are a popular material, widely used in the production of common daily products. In the following article, TAELIM will share information about this type of plastic with its outstanding features and applications for you to understand.

Learn a little about PVC resin

PVC resin, short for Polyvinyl Chloride, is a thermoplastic produced through the polymerization of Vinyl chloride. This is one of the earliest plastics in the plastics industry, discovered in 1835 and not officially produced on a large scale until 1937. Currently, PVC has become an alternative to many other materials, helping to optimize efficiency and reduce production costs.

PVC resin is solid, odorless and usually white, but can also be produced in amber or colorless. With its outstanding advantages, PVC is now widely used in the production of water pipes, electric cables and many other industrial products. In terms of safety, PVC is basically non-toxic, but can be harmful if combined with some additives during the production process.

>>> See more: What Are Plastic Beads? What Types Are Common On The Market?

Outstanding features of PVC plastic beads

PVC plastic, one of the earliest plastic particles in the history of the plastic industry, has many superior properties that not all types of plastic have. To better understand this plastic material, let's take a look at some of its advantages and disadvantages, specifically as follows.

Special advantages of PVC plastic beads

Nowadays, this material is widely used in the production of common items. Below are some outstanding features of this type of plastic for you to understand:

- Outstanding chemical resistance: PVC plastic is resistant to a wide range of chemicals, ensuring durability in harsh environments.

- Hydrolysis resistance: PVC is resistant to the effects of hot water and steam.

- Anti-UV: This material can prevent the harmful effects of UV rays, protecting the product in outdoor conditions.

- Self-extinguishing and electromagnetic interference protection: Another special property of PVC is its ability to self-extinguish fire and prevent electromagnetic interference.

- Food safety: Virgin PVC resin is also used to manufacture products related to the food industry.

- Affordable: Compared to many other materials, PVC is affordable, making it suitable for many industries.

- Easy to combine additives: PVC can be mixed with fiberglass to increase hardness, better impact resistance, or metal additives for use in machinery and equipment, withstanding high temperatures up to 150°C.

Disadvantages of PVC plastic beads

Besides the outstanding features mentioned above, this material also has certain limitations, specifically as follows:

- Poor durability in low temperature conditions: When exposed to cold environments, the durability of PVC may be reduced.

- Poor abrasion resistance: PVC is not resistant to strong abrasion and is easily affected by harsh physical agents.

- Flammable at high temperatures: When exposed to temperatures above 120°C, PVC is flammable and emits an unpleasant odor.

Applications of PVC plastic particles in life

With the detailed sharing above, PVC plastic not only has outstanding properties but is also widely used in many areas of life. From the production of construction materials to consumer products, PVC plays an important role with many different applications. Below are some common applications of this special plastic for you to understand.

Vinyl flooring from PVC plastic granules

Vinyl flooring, especially imitation wood flooring, is commonly used in many modern constructions. With the main ingredient being PVC plastic, this product has high durability, excellent water resistance, moisture resistance and slip resistance. Thanks to that, Vinyl flooring is not only highly aesthetic but also very suitable for weather conditions in Vietnam.

>>> See more: Applications of PVC Plastic and Notes When Using

PVC plastic in plastic pipe production

PVC resin is the main raw material in the production of plastic pipes, often used to carry water and other liquids in households, factories or industrial zones. Depending on the needs of use, PVC pipes can be divided into the following types:

- Rigid PVC pipe: Does not contain plasticizers, often used for high pressure systems.

- Soft PVC pipe: With added plasticizers, it is more flexible and is often used in lighter applications.

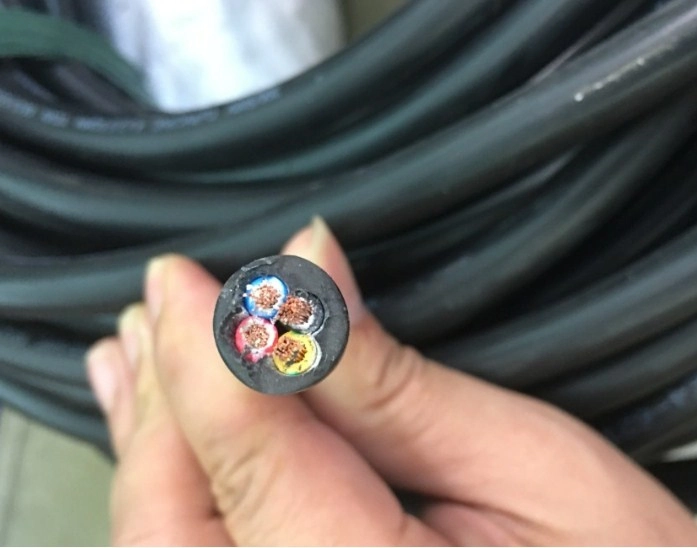

Manufacture of electric wires and cables

With excellent electrical insulation, PVC resin is an ideal material for the production of electric wires and cables. To increase safety, manufacturers often add fire retardant additives during the production of cables, helping to ensure safety during use.

PVC plastic film in packaging production

PVC resin is also used to produce plastic films for packaging, raincoats, and other protective products. Depending on the requirements of use, PVC can be produced into: rigid films, semi-rigid films, and soft films. These types of films are often adjusted by adding additives to achieve the flexibility and hardness suitable for specific applications.

Recently, TAELIM has shared detailed information about PVC plastic granules with outstanding features. With diverse applications, PVC plastic continues to be one of the indispensable materials in many industries today.

>>> See more: 1001 Great Benefits of Purchasing and Recycling Waste Paper

TAELIM International Transport Company Limited

With the desire to support the development of the plastic industry by providing high quality plastic pellets and services. Taelim Plastic is one of the Vietnamese plastic companies with many years of experience, with a long history of development, specializing in the production, trading, import and export of recycled pellets. By applying advanced technology, meeting European standards with a strict process, we ensure to bring customers the best products and services.

ADDRESS: SH109 Vinhomes Marina, Hai Phong

PHONE: (+84) 9815 888 16

EMAIL: hatnhua.taelim@gmail.com