Recycled ABS plastic is widely used in daily life with excellent environmental protection properties. In the following article, TAELIM will share information about this type of plastic with outstanding features and specific applications for you to understand.

Introduction to recycled ABS plastic

Recycled ABS stands for Acrylonitrile Butadiene Styrene (chemical formula: (C8H8· C4H6·C3H3N)n), is a opaque thermoplastic resin that features good mechanical and thermodynamic properties. The “thermoplastic” nature of ABS means that when the resin is heated to its melting point and then cooled again, its quality remains unchanged.

The most common method for producing recycled ABS plastic is to mix three main components: acrylonitrile, butadiene and styrene, and then heat them to form a plastic mixture. In addition, additives such as catalysts, hardeners and stabilizers are also added to improve the properties of ABS plastic. This type of plastic is easy to process, cheap and has a strong structure, so it is very popular in the consumer goods manufacturing industry such as camera cases, computer keys, helmets, protective cases, printers and ink cartridges.

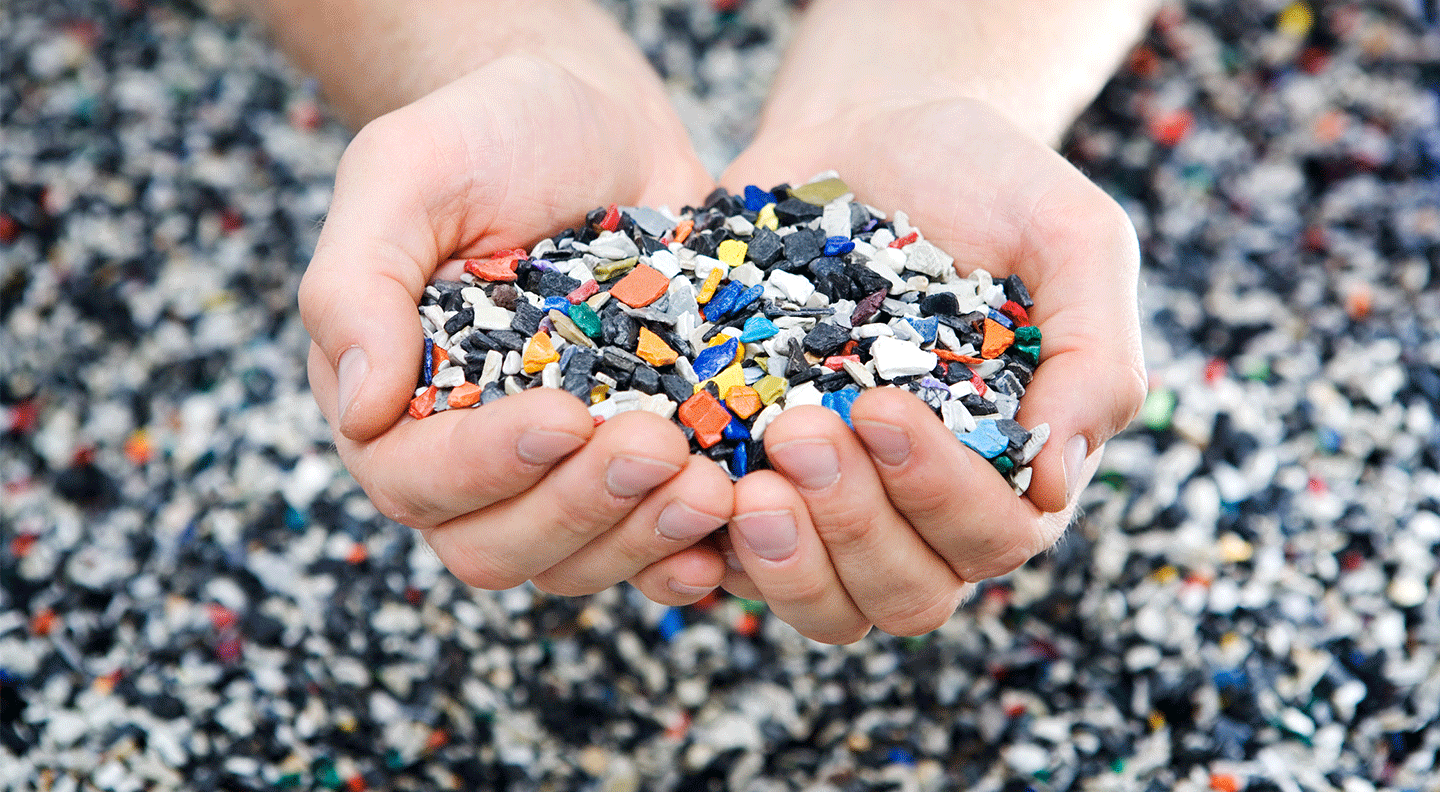

When these products are damaged and beyond repair, they are collected, crushed, melted and molded into a new form of plastic, called recycled ABS plastic.

>>> See more: What is Plastic? Applications of Plastic in Life

Components of recycled ABS

Recycled ABS is made up of three main components, namely:

- Acrylonitrile: An organic compound with the chemical formula C3H3N, which helps increase the hardness and mechanical strength of ABS plastic.

- Butadiene: Organic compound with the formula C4H6, providing elasticity and impact resistance to the product.

- Styrene: With the chemical formula C8H8, this is the compound that provides gloss and heat resistance to ABS plastic.

In addition to the three main ingredients above, depending on the requirements of the final product, manufacturers can add additives such as flame retardants, antistatic agents, colorants or anti-corrosion agents.

Advantages and disadvantages of recycled ABS plastic

Nowadays, this type of plastic is widely used in the market, creating popular products. Below are their characteristics with detailed advantages and disadvantages for you to understand.

Advantages of recycled ABS

With such popularity, this type of plastic has many specific superior characteristics as follows:

- Environmentally friendly: Using recycled ABS plastic helps to reduce waste and optimize resource use, thereby limiting the negative impact of new plastic production.

- Reduced Costs: Recycled ABS plastic is often cheaper than new plastic, reducing processing costs and benefiting both manufacturers and consumers.

- Stable physical properties: Even after multiple crushing and recycling cycles, recycled ABS retains the same physical properties as new ABS plastic.

Disadvantages of recycled ABS plastic

Besides the above advantages, this type of plastic also has some limitations, specifically as follows:

- Uneven quality: The screening and production process of recycled ABS at factories can be different, leading to inconsistency and the quality of the output product is not guaranteed.

- Difficult to control purity: During the recycling process, impurities may not be completely removed, thereby affecting the quality of the final product.

- Difficult to preserve: Recycled ABS plastic is easily damaged by sunlight, requiring manufacturers to invest in preservation.

Applications of recycled plastic granules

Recycled plastic pellets are now widely used in many industries. Some typical fields include construction, household goods manufacturing, packaging, and many recycled plastic products with diverse designs and colors. For example, products such as plastic tables and chairs, plastic pallets, and plastic packaging are often made from recycled plastic pellets.

The plastic recycling process involves collecting waste, crushing it into small, uniform-sized pieces, cleaning it, drying it, and melting it to form a plastic stream. This liquid plastic stream is then extruded, pressed into fibers or pellets, cooled, and cut into plastic pellets. Each type of plastic has its own recycling process, and recycled plastic is often used in manufacturing in the garment industry and in the production of plastic packaging.

>>> See more: Recycled ABS Production Process and Common Additives

Recently, TAELIM introduced recycled ABS plastic with its basic characteristics and applications. Hopefully, through this, you have a better understanding of this type of plastic and choose for yourself a reputable plastic granule manufacturing facility.

TAELIM International Transport Company Limited

With the desire to support the development of the plastic industry by providing high quality plastic pellets and services. Taelim Plastic is one of the Vietnamese plastic companies with many years of experience, with a long history of development, specializing in the production, trading, import and export of recycled pellets. By applying advanced technology, meeting European standards with a strict process, we ensure to bring customers the best products and services.

ADDRESS: SH109 Vinhomes Marina, Hai Phong

PHONE: (+84) 9815 888 16

EMAIL: hatnhua.taelim@gmail.com